Specialroll

The most economical roller designed to be used under standard working conditions in the preheating and cooling zone and, even for light wall tiles in the firing zone.

diamorph hob certec offers a full range of ceramic rollers that are used by producers of ceramics as essential parts of kilns and by kiln manufacturers. We have developed special products that suit each type of kiln.

Ceramic rollers

Cement boards

Hot gas filters

The most economical roller designed to be used under standard working conditions in the preheating and cooling zone and, even for light wall tiles in the firing zone.

Superroll has a higher module of elasticity than Specialroll, and this is why it is possible to install it under higher loads. This ceramic roller constitutes an economical option in the hob certec portfolio, and it is to be used in firing zone with heavy wall and floor tiles.

Economical version of Hyperroll-NG to be used in those cases when the thermal shock resistance is not the main priority, but it is still necessary to use a high specification technical ceramic roller.

It is a roller with a high module of elasticity which allows using it in the firing zone when the rollers work in clean conditions and under moderated chemical attack.

This roller has been designed considering all the factors that influence the thermal shock resistance of a ceramic roller. These factors include the thermal expansion coefficient, thermal conductivity, modulus of elasticity, chemical contamination inside the kiln, porosity, roller size, and more.

It is the roller with the highest thermal shock resistance available in the market. The operating costs of running the kiln are reduced because, in many cases, rollers can be extracted from the firing zone even at maximum temperatures without any breakages. Additionally, the high modulus of elasticity helps maintain the quality of tiles in optimal condition.

A technical roller specifically designed to withstand the highest loads in the firing zone, Hyperroll-X is the preferred choice for any area of the kiln where other materials fail to provide sufficient tile support due to the weight of the tiles or the dimensions of the rollers.

In recent years, as kiln sizes have increased, more and more kiln users are opting to install this state-of-the-art roller design in greater numbers.

For optimal kiln operation and achieving the highest output of premium quality tiles, Hyperroll-D (Dense Nano) is the unrivaled ceramic roller available in the market. It possesses two key advantages: zero porosity and very high modulus of elasticity (MOE). These characteristics contribute to superior performance in tile transportation and final tile quality by minimizing roller bending.

The zero porosity of Hyperroll-D also provides exceptional resistance against chemical attacks.

Hyperroll-D delivers the best results when installed from the kiln entrance up to the first module, as this is where chemical and physical pollution are most prevalent. It is crucial to install these rollers at temperatures of 650 °C or below.

Universal Intelligent solution for production of all kinds of quality tiles in terms of planarity, straight trajectory in the kiln, reduction of defects and deformations.

Hyperroll IQ offers a unique combination of benefits, including chemical resistance, thermal shock resistance and strength. As a result, Hyperroll IQ can be effectively utilized in every module of a roller kiln.

Hyperroll EXTREME is the most extreme roller in the world ,with MOE of 200 GPa.

This roller has been designed to withstand the most extreme loads 20-50 mm of tile thickness.

This unique roller enable to charge the maximum width of kilns channels with tiles in order to use their production capacity with maximum efficiency.

Thanks to its very low porosity the roller resists very well to aggressive chemical attack.

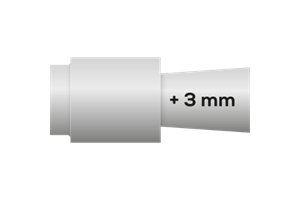

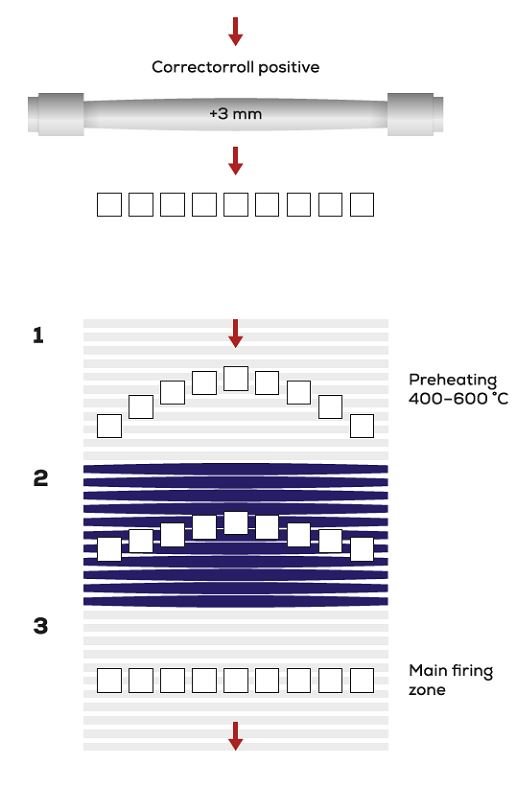

A roller designed with up to 3 mm of correcting diameter difference.

By accelerating the tile transport speed in the middle of the kiln, Correctorroll ensures improved tile quality with flatter surfaces and minimized deformations along the edges. Moreover, the enhanced alignment allows for increased kiln capacity as more tiles can be efficiently placed in the furnace. Correctorroll is available in different roller materials to cater to various working conditions.

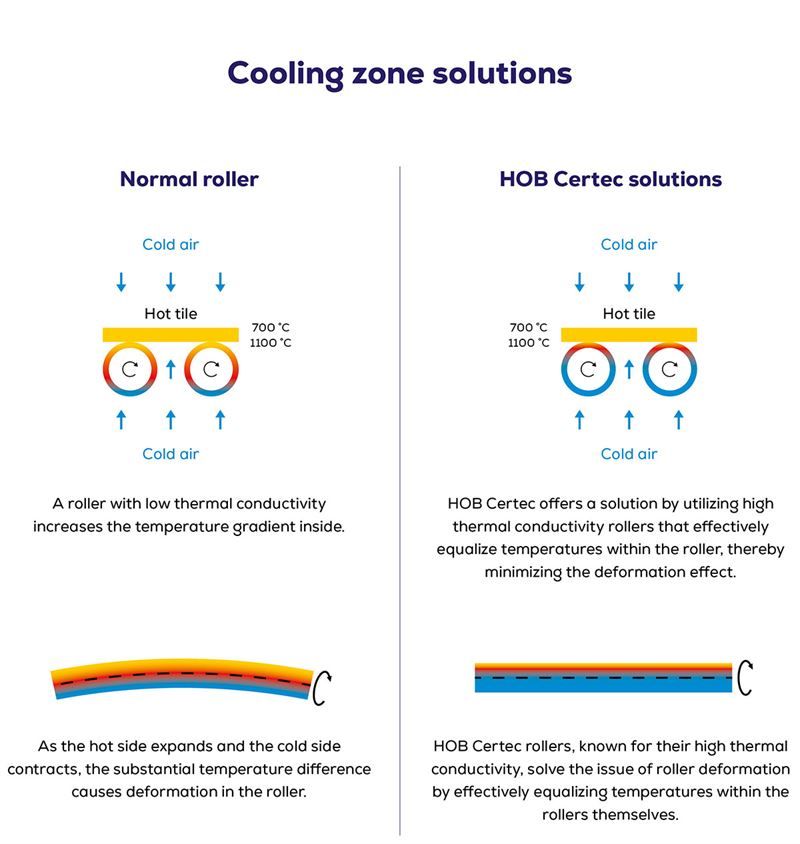

The rapid cooling zone possesses distinctive characteristics that require careful consideration and detailed analysis. In this area, tiles undergo a rapid and delicate process that can significantly impact their final quality. The upper side of the roller meets the hot tiles emerging from the firing zone, while the lower side is exposed to the cold air. The elevated temperature causes the upper surface to expand.

The temperature difference and resulting expansions are the primary causes of roller deformation in the rapid cooling zone. When searching for the optimal roller material for this area, it is crucial to analyze two key factors:

By considering these factors, the selection of an appropriate roller material can greatly mitigate roller deformation and optimize the production process.

A rigid roller with zero porosity and increased thermal conductivity designed to minimize roller deformation in the rapid cooling zone.

The HYPERROLL GR is a high-performance roller, meticulously engineered to withstand the rigorous working conditions within the rapid cooling zone. With its nearly zero porosity and exceptional thermal conductivity, this roller is designed to prevent deformation and ensure the preservation of tile quality during the fast and delicate processing phase.

Our new hyper-technical, HYPERROLL RCX, is specifically engineered for high-performance use in severe conditions within the rapid cooling zone. Boasting an impressive MOE of 185 GPa and a thermal conductivity of 9.6 W/m. K-1, it offers the ultimate solution for demanding applications where strength and heat transfer performance are crucial factors.

The best ceramic roller solution for the rapid cooling zone

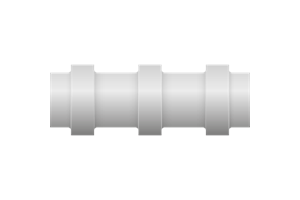

The Superringroll provides a significant enhancement to the quality of tile production by facilitating a uniform cooling process in the rapid cooling zone. Its innovative design is specifically tailored to minimize deformation in this area by reducing the contact area between the roller and the tile.

By effectively reducing the internal thermal tension within both the roller and the tile, the Superringroll enables a more consistent distribution of heat between the two surfaces. This is achieved through the efficient flow of cold air, ensuring optimal performance and results.

+420 378 010 910 |

sales@certec.cz htsales@tenmat.com |

Tovarni 739 330 12 Horni Briza |